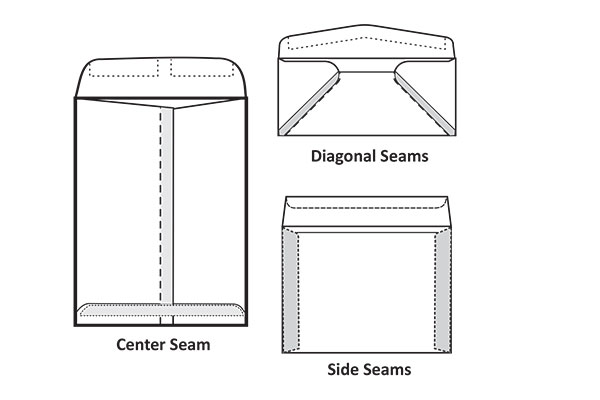

Envelope seams are typically permanently sealed for durability.

Envelope seams are typically permanently sealed for durability

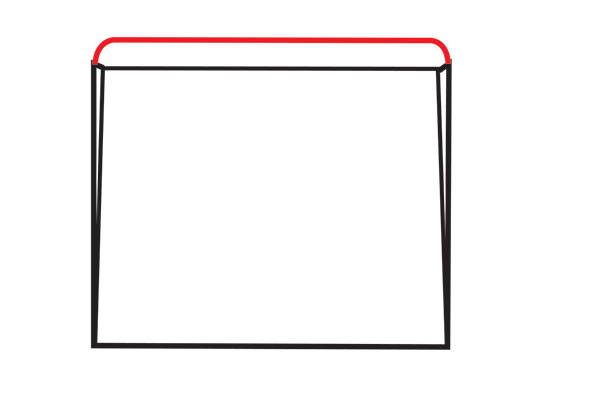

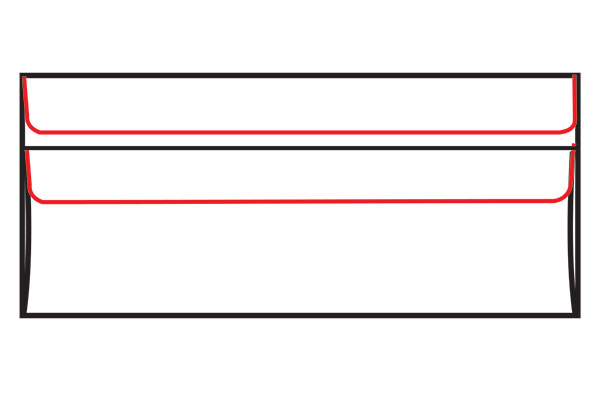

Used on commercial style envelopes to provide additional sealing area.

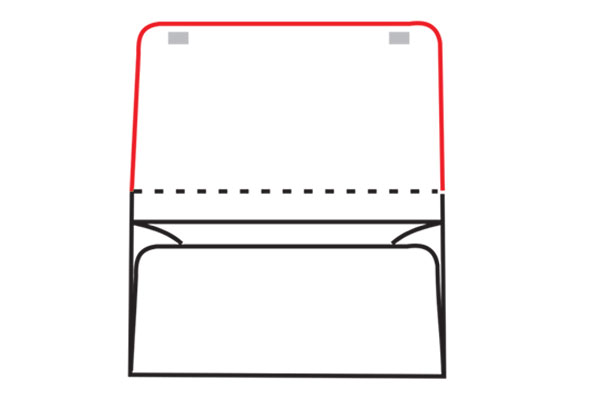

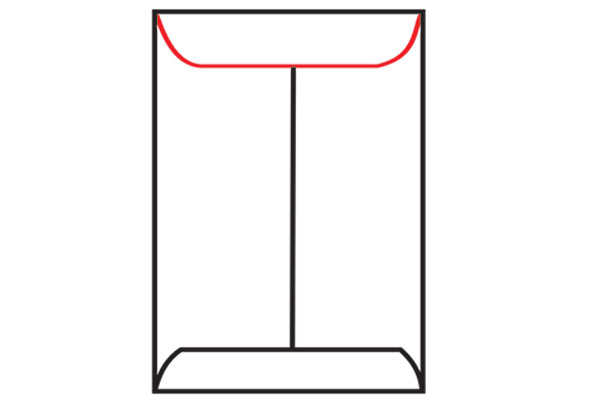

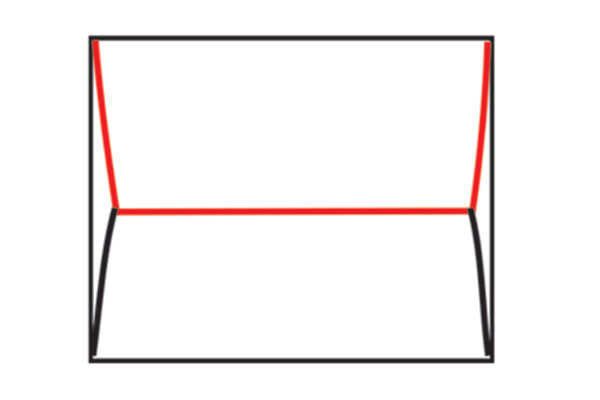

Constructed without a flap, but rather with an extension of the face, neither gummed nor scored, to assist with material insertion.

Latex adhesive is applied on two flaps and separated until sealing.

Used on catalogs

Used on booklets and machine insertables.

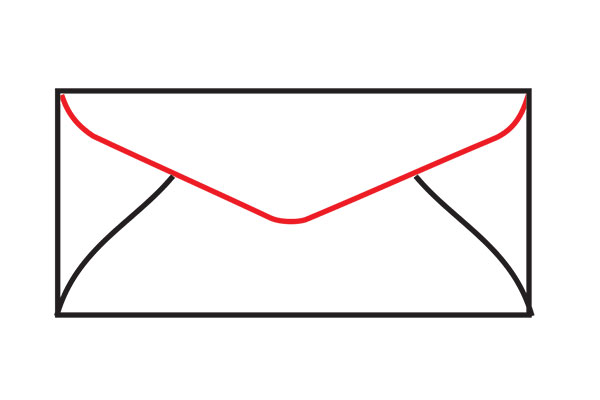

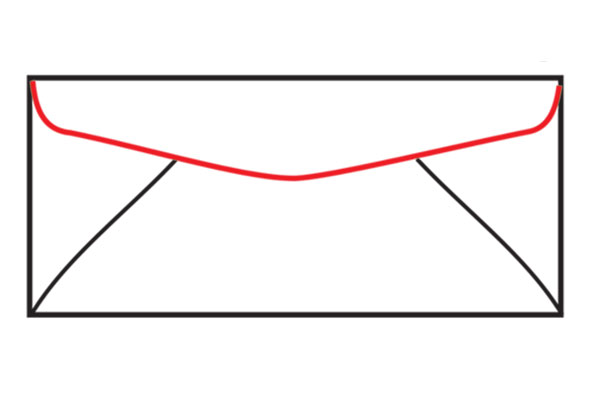

Used on #7-1/2 envelope flaps.

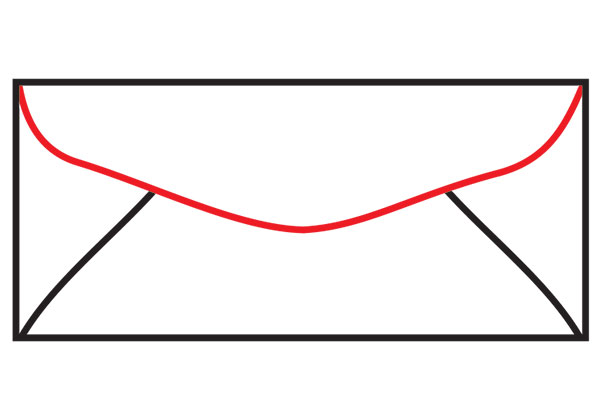

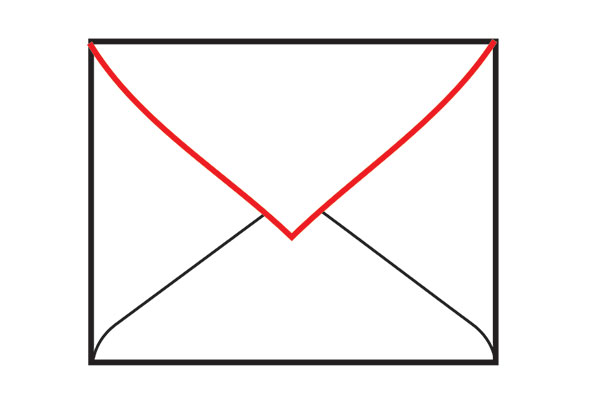

Used on most baronials.

Used on some small coin, drug and pay envelopes

Used on our Church Offering envelopes.

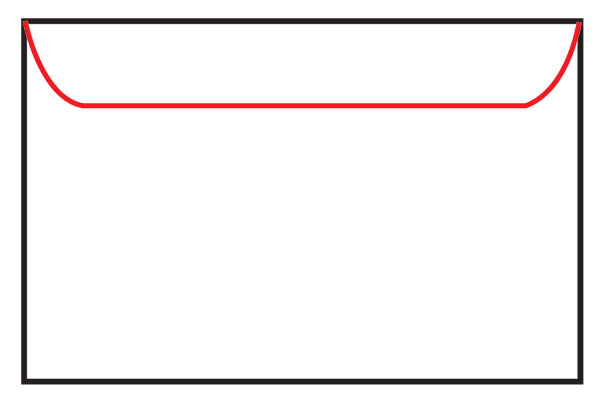

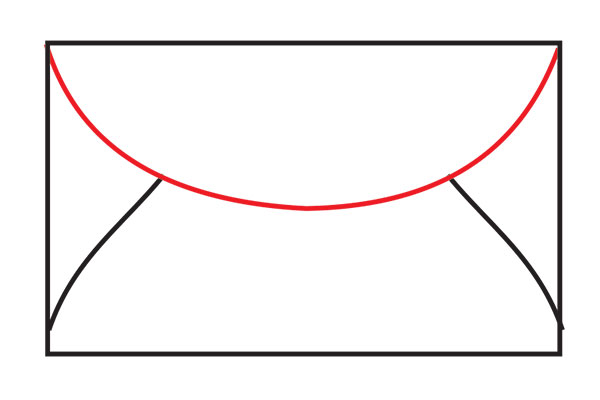

Used on announcements and some booklets.

Used on commercials

Provide additional area for printing on both the back and seal flap; used on dual purpose, some commercials, collections, and order-form envelopes